Industry news

8

September

Prototype Manufacturing of Plastic Products: Silicone Molding

September 8, 2025

This is a highly common and efficient rapid tooling method, particularly suitable for producing small batches (typically from a few to dozens of units) of plastic prototypes or parts with…

30

August

Types of Materials Suitable for CNC Machining of Plastics

August 30, 2025

CNC machining of plastics can handle a very wide range of materials, covering almost all common industrial-grade solid engineering plastic sheets, rods, or tubes.This is a core advantage of CNC…

30

August

Plastic Prototype Processing Techniques

August 30, 2025

The processing techniques for plastic prototypes are highly diverse. The choice of which method to use primarily depends on factors such as product requirements, quantity, material, precision, cost, and lead…

30

August

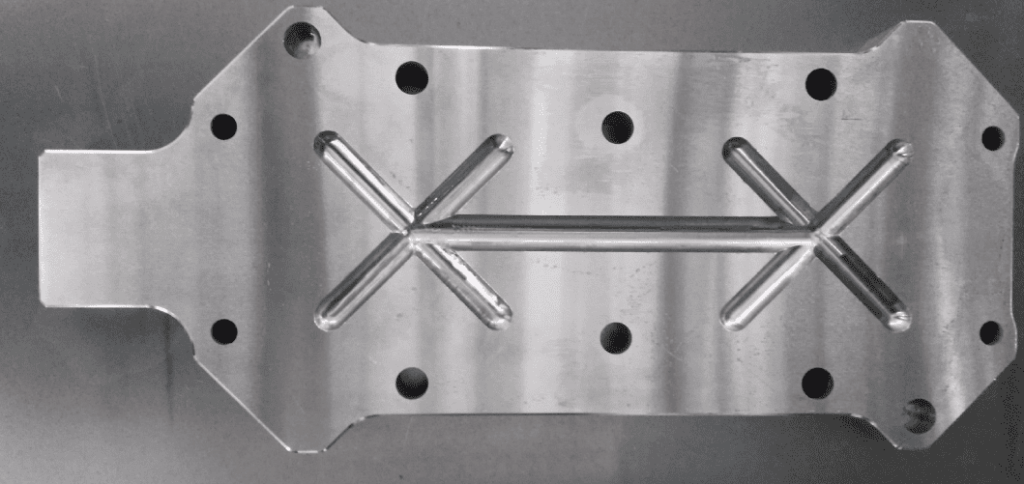

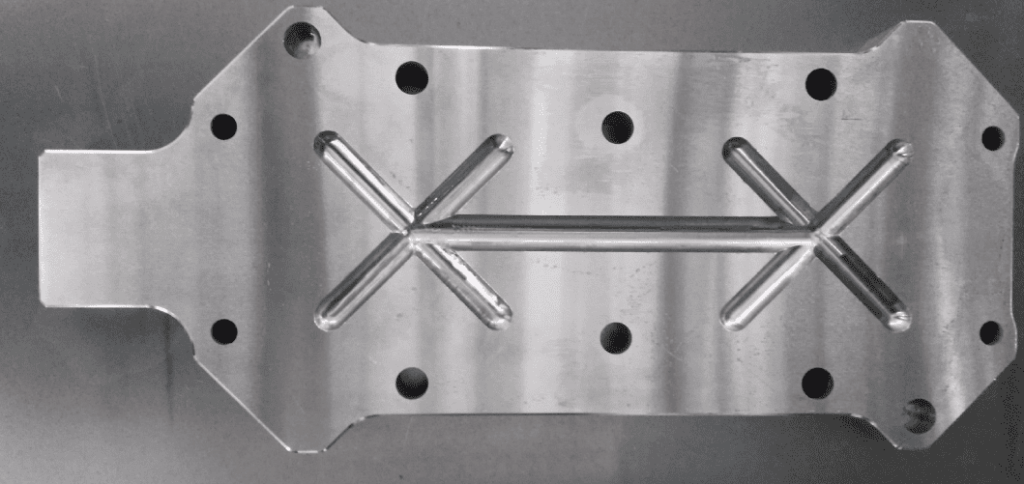

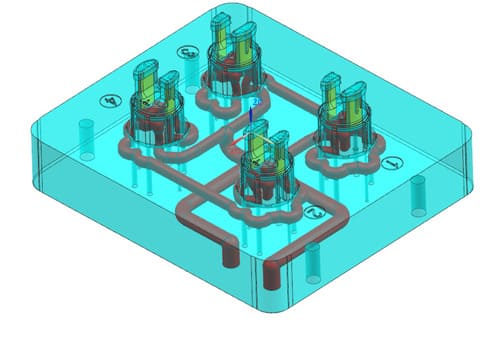

Use of Diffusion Bonding Technology in Injection Molds 2

August 30, 2025

Diffusion bonding is indeed a critical technology for addressing manufacturing challenges in injection molds, particularly for conformal cooling systems. By enhancing cooling efficiency, it directly contributes to significant improvements in…

28

August

Use of Diffusion Bonding Technology in Injection Molds 1

August 28, 2025

Diffusion bonding technology indeed offers significant benefits in injection mold applications, particularly in enhancing cooling efficiency and extending mold lifespan. Introduction to Diffusion Bonding Technology Diffusion bonding is a solid-state…

30

August

Injection Mold Life Influencing Factor Analysis

August 30, 2025

The service life of an injection mold is a comprehensive issue, deeply influenced by multiple stages such as design, manufacturing, usage, and maintenance. Mold life typically refers not to time,…

26

August

Precautions for Injection Molds Before Transporting the Molds.

August 26, 2025

The preparation work for injection molds before transportation is crucial, as it directly affects the safety, service life, and smoothness of subsequent production. Core Objectives Ensure that the molds during…

18

August

AI system applied to injection mold manufacturing

August 18, 2025

AI-Driven Process Optimization in Injection Molding Production The injection molding industry is undergoing a transformative shift with the integration of artificial intelligence (AI) and smart manufacturing technologies. Traditional methods of…

17

August

3D Printing Revolutionizes Plastic Mold Manufacturing

August 17, 2025

The application of 3D printing technology in plastic mold manufacturing has brought significant advancements to the industry. This innovative approach enables the rapid production of complex mold components, reducing production…

30

August

Adapter injection molding product materials

August 30, 2025

Common Materials for Injection-Molded Pipe Fittings The materials commonly used for injection-molded pipe fittings are listed below, with the selection depending on application scenarios, performance requirements, and cost considerations: Selection…