About ATC-Mould®

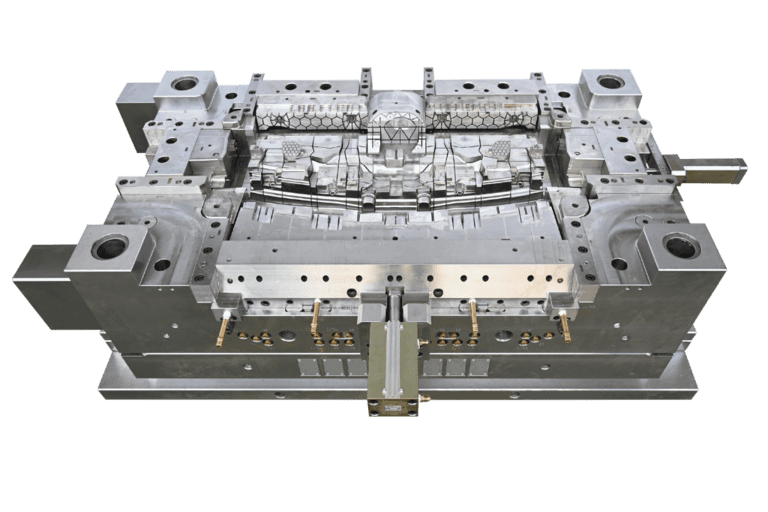

ATC-Mould was founded in 2011, The manufacture is located in Shenzhen and owns workshops totaling 3000 square meters and more than hundres employees. ATC-Mould is specializing in the development, design, manufacture and precision injection of precision plastic moulds with its products targeted at precision moulds for automobiles, electric tools, household appliances and watercrafts. The company is technically powerful as it is equipped with high-level designers and well-experienced technicians, over 100 processing devices accommodating all processing requirements. Under the tenet of “product quality is the life of the company”, the objective of “precision products with zero defect” and the operation value of “quality first, efficiency highlighted, customers oriented”, the company sticks to innovation, strives for perfection and keeps surpassing ourselves in an effort to create top-quality moulds for customers. With the principles of seeking growth in cooperation, winning customer’s trust with sincerity and fulfilling our commitment with actions, the company has established long partnership with world famous enterprises and has sold its products to Europe, North America, Japan and Mexico, supplied conforming products to Honda, Toyota, Volvo, Philips and won high recognition from customers.

As our company grows in step with your evolving project demands, we have substantially strengthened our capabilities in both plastic injection molding production and precision CNC machining for metal and hardware parts.

Today, we deliver end-to-end manufacturing excellence — from initial concept through prototype injection molding and CNC machined prototypes to full-scale production injection molding and high-volume CNC machining services.

Our rapid prototype injection molding uses fast aluminum tooling and production-grade resins to produce functional, testable plastic parts quickly and affordably, enabling faster design validation and smoother transitions to mass custom injection molding.

Complementing this, our precision CNC machining capabilities — including 3-axis, 4-axis, and 5-axis CNC milling, CNC turning, and tight-tolerance custom CNC parts — deliver superior surface finishes and complex geometries in metals (aluminum, stainless steel, titanium, brass) and engineering plastics, ideal for prototypes, bridge production, and demanding end-use components.

, we provide seamless prototype-to-production solutions, expert DFM support, competitive lead times, and consistent quality to help accelerate your product launches and reduce development risks.