Material Selection for Rapid Prototype Molds

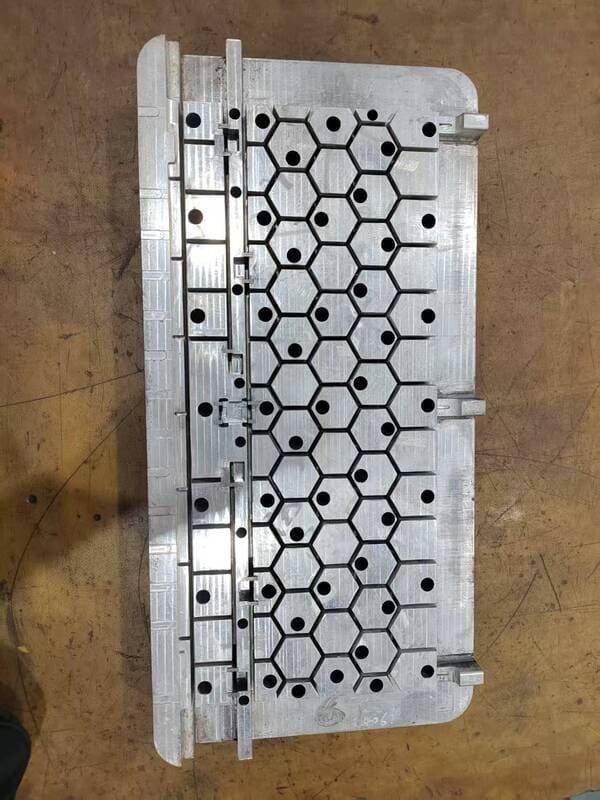

For small-batch, fast-turnaround experimental molds, we typically recommend S50C steel or aluminum due to their cost-effectiveness and quick machining time. These materials are suitable for functional testing or low-volume production, with an expected mold life ranging from 500 to 5,000 shots, depending on factors such as part geometry, injection pressure, and material abrasiveness.

However, these options are not ideal for high-gloss or Class-A surface finishes (A3 or above). Aluminum molds may develop wear marks or slight texture variations over time, while S50C steel lacks the polishability and durability of premium mold steels.

For parts requiring excellent surface quality, we recommend higher-grade steels such as:

P20 (1.2311) – Better polishability, suitable for mid-volume production.

NAK80 (1.2738) – Pre-hardened, mirror-finish capable, longer lifespan.

S136 (1.2083) / Stainless steels – For corrosion resistance and ultra-high gloss.

In summary:

S50C & Aluminum = Fast, low-cost, short lifespan (500–5,000 shots).

Premium steels (P20, NAK80, S136) = Better finish, durability, and higher mold life.

Choosing the right material depends on budget, required surface quality, and production volume. For prototypes or non-cosmetic parts, S50C and aluminum are practical choices, but for high-end finishes, investing in superior steel is necessary.